High-speed crystallization screening

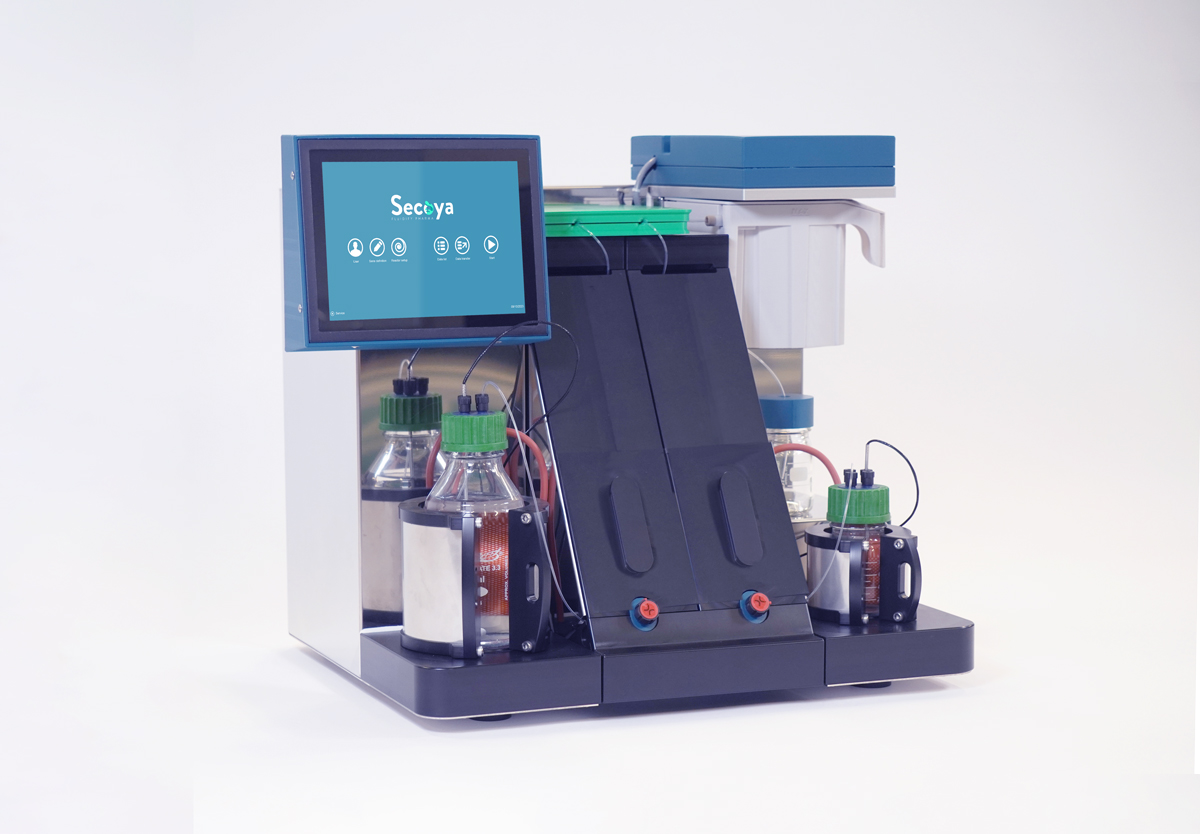

The Secoya Crystallization Technology SCT-LAB instrument has a fully integrated stock solution heating and agitating position, allowing to dissolve the molecule of interest inside the instrument without further handling required.

The accessibility of the mixing inserts and reactor has drastically improved, with a guaranteed watertightness of the reactor holder without the use of screws and bolts which enables the user to more rapidly exchange the reactor, without any fuss.

Heat flow studies have pointed out the increased thermal stability of the machine inside the syringes, transfer tubing, inserts and reactor so that heating and cooling is much more effective and uniform.

The tubing connecting the syringes and inserts are now maintained in the same heated and cooled compartment to avoid clogging before the product enters the inserts. It comes equipped with a dedicated thermostat from Huber Kaltemaschinebau, software controlled by our compliant software.

Struggling to achieve a targeted particle size distribution in your crystallization screening process?

Secoya’s Crystallization Technology revolutionizes this process through spontaneous nucleation, making it both faster and more efficient. In this video, Bart Rimez demonstrates the simplicity and speed of the SCT process, enabling labs to screen up to three different crystal sizes within just 15 minutes, all while achieving a narrow particle size distribution.

Precise temperature control optimazing nucleation

Multiple mixer inserts

enhancing versatility

Whether you want to cool crystallization or crystallize the antisovlent, the instrument seamlessly integrates several microfluidic mixers which are positioned right before the entry of the reactor.

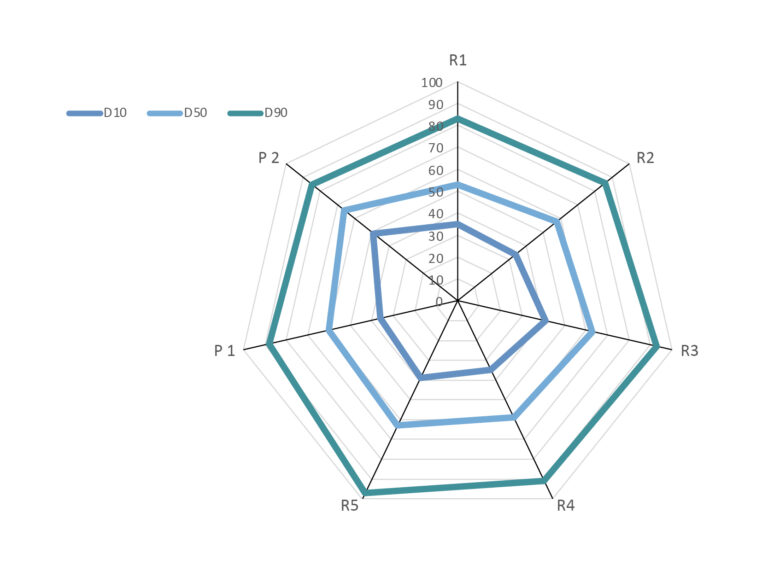

Lactose crystallization tests: extrapolation of results using identical parameters for both lab scaled testing (R1-R5) and pilot testing (P1 and P2).

Secoya Crystallization Technology,

Seamless scale up from lab test to production validation

eXAMPLES OF Application

Upscaling lactose crystallization towards a full continuous crystal production

Continuous Microfluidic Antisolvent Crystallization as a Bottom-Up Solution

for the Development of Long-Acting Injectable Formulation

– WHITE PAPER: CRYSTALLIZATION PROCESS FOR HIGH QUALITY API

– APPLICATION NOTE: THE USE OF DIFFERENT INSERTS FOR ANTISOLVENT CRYSTALLIZATION

– PUBLICATION: Nandi, S. et al., Continuous Microfluidic Antisolvent Crystallization as a Bottom-Up Solution for the Development of Long-Acting Injectable Formulations. Pharmaceutics 2024, 16, 376. https://doi.org/10.3390/ pharmaceutics16030376

| Description | Product |

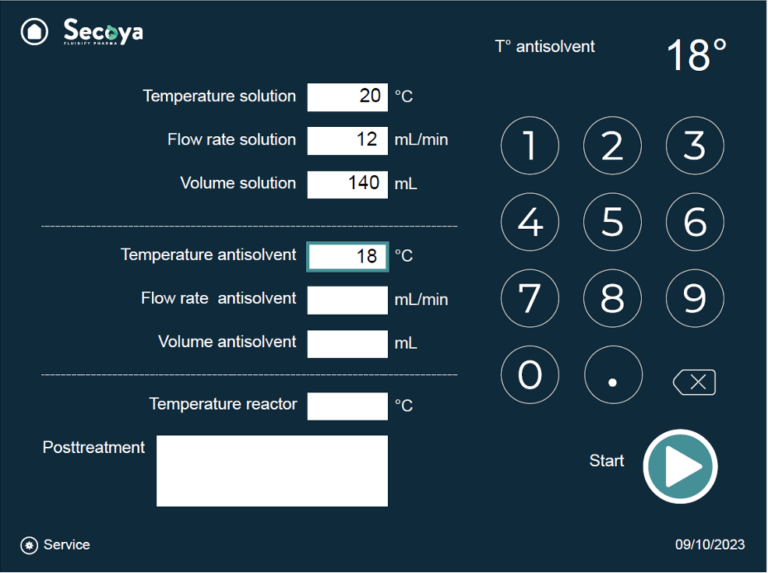

| Temperature antisolvent | from 5 to 85 °C (antisolvent precooled in fridge) |

| Temperature solution | from 25 to 85 °C |

| Temperature reactor | from 0 to 75 °C, agitated |

| Volume stock solution | 100 mL, agitated and heated in place |

| Volume stock antisolvent | 250 mL, agitated and heated in place |

| Volume solution per test | from 1 to 20 mL, syringes are preheated and precooled |

| VFlow rate solution and antisolvent | from 1 to 50 mL/min |

| 6 mixing inserts for cooling and antisolvent crystallization | |

| 7 different reactors for cooling and antisolvent crystallization | |

| Unit dimensions | 45 x 45 x 45 cm (L x W x H) |

| Weight | 28 kg |

Want to know more about the SCT-LAB 2.0?

Want to know more about the SCT-LAB 2.0?

| Thank you for Signing Up |