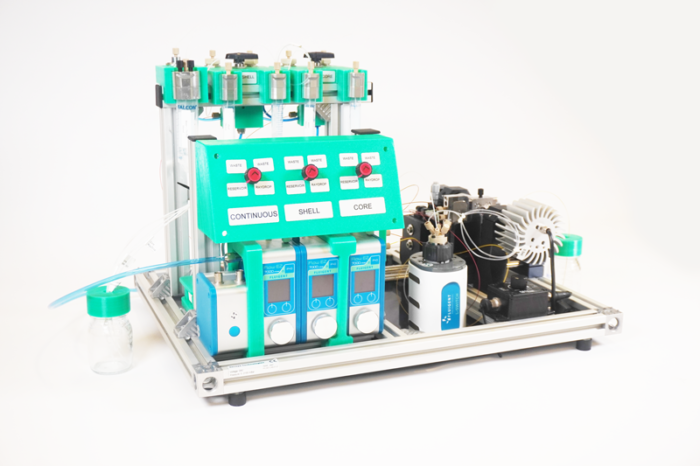

RayDrop Platform

Are you looking to use your FACS equipment with encapsulated cells ?

The RayDrop Platform for cell encapsulation prior to sorting in FACS equipment (Fluorescence-Activated Cell Sorting) is a specific version of the RayDrop Platform that enables biological products to be encapsulated in double emulsions (DE) made up of a thin shell of oil surrounding an aqueous core. This one step method of encapsulation is made compatible with FACS thanks to both the size of the DE down to 25 µm which fits most FACS nozzles and the use of a water/oil/water DE that is compatible with sorting based on the application of an electric field.

Moreover, this RayDrop Platform includes a comprehensive flow path with pressure controllers, filters, flowmeters, and valves to ease the start-up, shutdown and cleaning of the system. An injection loop is connected to the core phase to produce samples with limited amounts of material. Thanks to the RayDrop® droplet generator, double emulsions are produced in one step at high-throughput, allowing the production of about 25 samples in a half day. A suitable optical system guarantees the optimum visualization of the emulsion production process inside the RayDrop®. The open design of the platform allows its adaptation to the customer’s needs.

Perfect control of emulsion production

The Secoya emulsification technology is based on the integration of the most efficient microfluidic technologies in a robust stainless-steel equipment.

The way we produce droplets, particles and capsules relies on the use of couples of capillaries perfectly aligned in a metallic reservoir. The first capillary is terminated with a 3D-printed nozzle and injects the droplet phase in the junction. The second one is the only output of the system, so it collects both phases, the droplet phase and the continuous phase filling the reservoir under pressure.

The droplets are produced by the controlled squeezing of the droplet phase by the continuous phase at the entrance of the collection capillary

| Category | Description |

| Injection loop (from Fluigent) | • 6-port/2-position bidirectional recirculation valve Easy to sterilize with ethanol (injection loop and each tubing in contact with the cargo) |

| Working volumes of cell solution | • Various sample loops available: 50 µL, 100 µL, 200 µL, 500 µL, 1 mL |

| Fluid handling system (from Fluigent) | • Pressure based pumps (Flow EZ 7 bar) • Injection loop on the core phase |

| Reservoirs (from our partner Fluigent) | • Continuous phase: 1*50mL Falcon tube • Shell Phase: 2*15mL Pcap Falcon tube • Core Phase: 2*15mL Pcap Falcon tube |

| Flow meters (from Fluigent) | • Continuous phase: 1*Flow unit L (max 1100 µL/min in water calibration) • Shell Phase: 1* Flow unit M (max 200 µL/min in HFE calibration) • Core Phase: 1* Flow unit M (max 120 µL/min in water calibration) |

| Optical system | • LED light source • Microscope objective (10X and 5X available) • USB3 colour camera (up to 400 fps, 1 μs integration time) • XYZ translation stages |

| Tubing |

• OD :1/16 and 1/32 OD • ID: 125 µm, 180 µm, 250 μm & 500 μm • Materials: PFA, PEEK |

| Filters | • 2 μm filter for all phases |

| Valves |

• 3*4 way manual valves • 2*2 way manual valves |

| Wetted materials | • Platform: PEEK, PFA, PCTFE, PTFE, SS316L, GLASS • Sealing: FKM or EDPM |

| Unit dimensions | 46 x 61 x 43 cm3 (L x W x H) |

| Weight | • 14 kg without the protective hood • 22.2 kg with the protective hood |

– BACTERIA AND YEAST ENCAPSULATION IN SMALL DOUBLE EMULSIONS

– CELL ENCAPSULATION IN SMALL DOUBLE EMULSIONS

– POLYMETHACRYLATE RESIN MICROCAPSULES SYNTHESIS

– PLGA MICROCAPSULES CREATION

– CHITOSAN MICROCAPSULES CREATION

Want to know more about the Raydrop platform aDAPTED TO FACS ?

Want to know more about the Raydrop platform aDAPTED TO FACS ?

| Thank you for Signing Up |