PERVAPORATION

An efficient and energy-saving technology for fluid separation

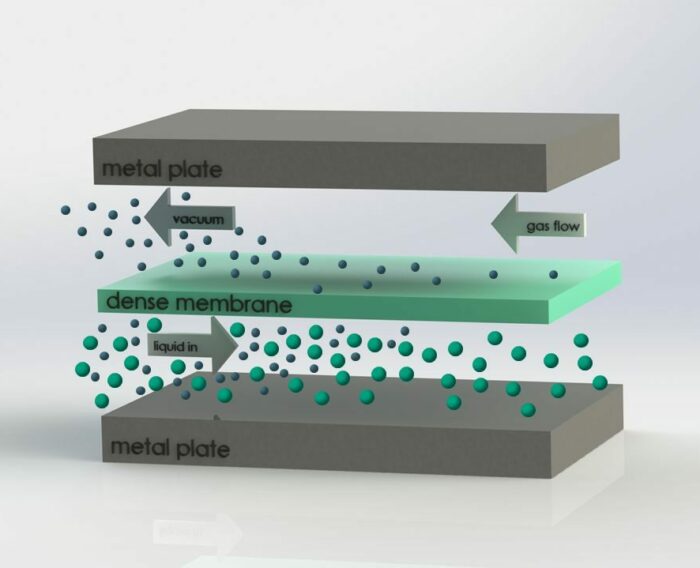

Pervaporation is a membrane separation process that is based on an energy-efficient combination of permeation and evaporation. It is applied to the removal of volatile compounds out of solutions through a selective membrane. By creating a vacuum or introducing a flow of purge gas on one side of a dense membrane, volatile compounds in a liquid flow diffuse through the membrane. By using selective membranes, pervaporation can be applied to the dehydration of organic solutions as well as to the removal of organic contaminants in an aqueous solution. In addition to its high energetic efficiency, due to the use of a dense membrane pervaporation is not subjected to azeotropic limitations.

Pervaporation integrated in a microfluidic device

For the sake of intensification and to perform the pervaporation process in a controlled environment, we have integrated the process in a microfluidic device, enabling a reduced footprint.

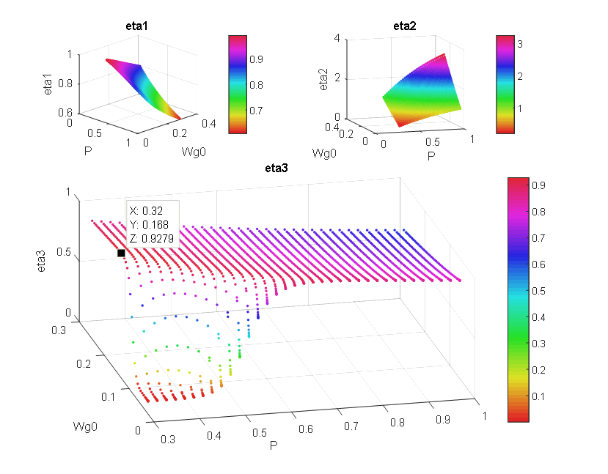

The modelling of the microfluidic pervaporation device associated with an optimisation algorithm allows us to identify the best outcome of the process based on the mixture thermodynamic properties. Therefore, we can easily evaluate the feasibility of the pervaporation process and propose a design. Subsequently, tests at a low scale should allow us to validate the model, after which the pervaporation device could be manufactured and instrumented.

Potentiel applications

-

The inline removal of alcohol from cell cultures to enhance their productivity

-

The intensification of esterification or imination reactions by equilibrium displacement

-

Liquid/Liquid separation in presence of temperature sensitive (bio-) products

-

Gas perfusion for processes

-

Concentration of an aqueous solution

List of publications:

Ziemecka, I.; Haut, B.; Scheid, B. Hydrogen Peroxide Concentration by Pervaporation of a Ternary Liquid Solution in Microfluidics. Lab. Chip 2014, 15 (2), 504–511.

Ziemecka, I.; Haut, B.; Scheid, B. Continuous Separation, with Microfluidics, of the Components of a Ternary Mixture: From Vacuum to Purge Gas Pervaporation. Microfluid. Nanofluidics 2017, 21 (5), 84.

Want to know more about the PERVAPORATION TECHNOLOGY?

Want to know more about the PERVAPORATION TECHNOLOGY?

| Thank you for Signing Up |