Background

Aspen API, a global supplier of active pharmaceutical ingredients (APIs), conducted a research project in collaboration with Secoya Technologies to improve its crystallization process. The goal was to achieve a robust and reproducible particle size distribution (PSD) without the need for micronization, which has posed challenges due to the sticky nature of certain APIs.

Objectives

To determine whether Secoya’s crystallization technology can achieve optimal PSD during crystallization, reducing or eliminating the need for micronization.

Materials & Methods

- API Selection and Solubility Curve Determination:

- Initial API concentration: 72 mg/ml in a 7:3 ethanol-water solution.

- Temperature range: Start at 70°C, cooling down to 5°C to determine the solubility curve.

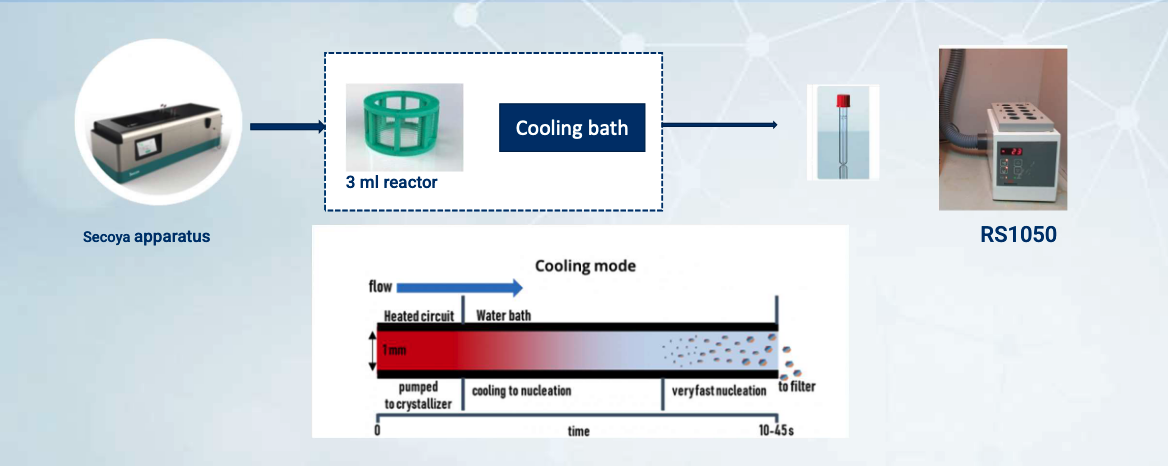

- Crystallization Setup:

- Reactor: 3 mL reactor coupled with Secoya cooling blocks (Cooling-0 and later Cooling-2).

- Cooling bath RS1050 maintained at 5°C.

- Flow rate: 20 ml/min with material collected and stirred at 5°C to initiate crystallization.

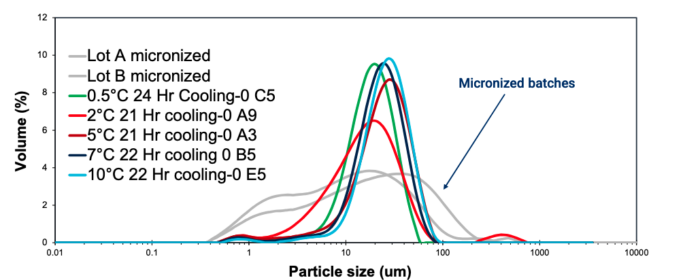

- Process Variables:

- Temperature control was crucial, with temperatures varying between 0.5°C and 10°C.

- Aging time in the reactor was also tested at intervals, such as 4½ hours and 24 hours, to observe PSD over time.

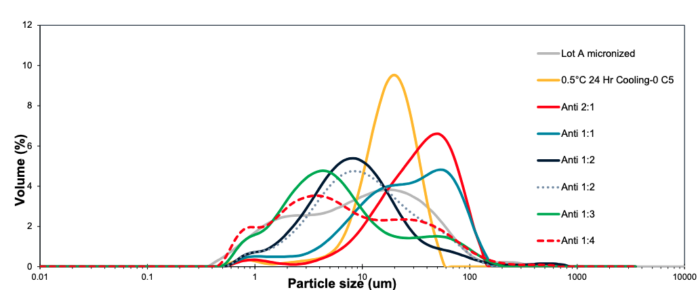

- Antisolvent Crystallization Trials:

- Concentration: 100 mg/ml in ethanol.

- Different solute-to-antisolvent ratios were tested, ranging from 2:1 to 1:4.

- Particle size and morphology were evaluated through visual inspection and PSD measuremen

Setup for cooling crystallization experiment

Results

Cooling Crystallization

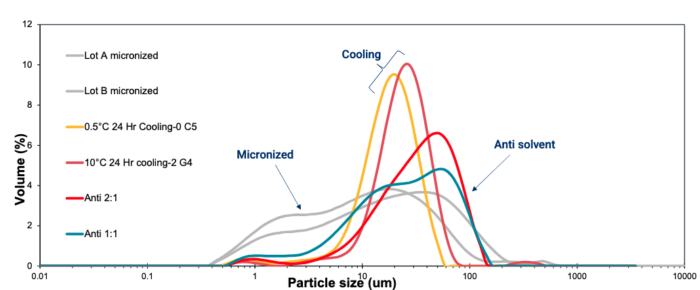

- Cooling crystallization gives a narrower distribution (PSD) than antisolvent for this AP (figure1)

- PSD of cooling crystallization is better than regular production (figure 2)

Anti solvent Crystallization

- Anti solvent gives a broader distribution (PSD) with smaller particles than cooling crystallization (figure3)

Conclusion

Cooling crystallization using Secoya’s technology has demonstrated potential as a method to achieve the desired PSD without the need for micronization.

Erik ter Voert

Sr. Lab. Technician at Aspen Oss B.V.

| Thank you for Signing Up |