What is API Crystallization?

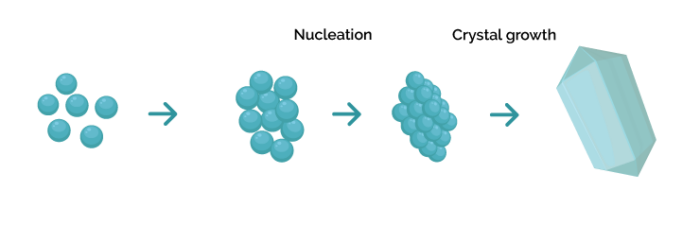

API crystallization refers to the process of transforming the active pharmaceutical ingredient (API) of a drug from a solution into a solid crystalline form. This is a crucial step in drug manufacturing because the crystalline form of an API can significantly influence its stability, solubility, uptake in the human/animal body and overall effectiveness. Crystallization also bridges the drug substance manufacturing and the drug product manufacturing towards its final application as a medicine. The process involves carefully controlling parameters such as temperature, solvent composition, and concentration to ensure the formation of crystals with desired properties (ex. crystals size, distribution).

Why crystallization is crucial

in drug product manufacturing?

Crystallization is crucial as the final step in drug product manufacturing because it directly affects the purity, stability, and reproducibility in production.

Crystallization helps in purifying the active pharmaceutical ingredient (API) by removing impurities. It ensures that the drug substance is consistent in its chemical composition, which is essential for the safety and efficacy of the medication

Crystalline forms of APIs are generally more stable than their amorphous (non-crystalline) counterparts. A stable crystalline form ensures that the drug has a longer shelf life and maintains its therapeutic effectiveness over time. Also the selection of the most stable polymorphic state – when more than one crystalline structure exists for one single molecule – is important to reach the highest possible shelf life.

Crystallization processes can be standardized to produce consistent batches of the API. This reproducibility is critical for ensuring that every dose of the drug performs the same way, which is a key requirement in pharmaceutical manufacturing.

Batch crystallized drug substances from solution

Crystallization in a large batch reactor in a manufacturing process is conducted in such a way that any variability in between two produced batches is reduced to an absolute minimum. In order to achieve this feature inside large tank sizes, the API is dissolved at elevated temperatures. While gently cooling, a preset quantity of solid API is added as very fine sized particles – called “seeds” – already having the features of the desired polymorphic form. During cooling, the API in solution will adhere to the crystalline seeds to generate grown crystals at the lowest possible temperature. To maximalize the efficiency of the process at the end usually an antisolvent is added to promote adhesion of the remaining API in solution to the crystals.

If this is executed in a very standardized way, the variability in between different produced batches is acceptable to be further treated downstream in the drug product manufacturing process steps.

What are the important parameters for the crystalline API in drug product manufacturing?

Once the crystalline API from the drug substance production is generated, during the drug product manufacturing, focus is set on the actual application of the API and its formulation. Other parameters come into play like the physical properties size and shape of the crystals, making a large part of the critical material attributes (CMA) of a drug product. Size, size distribution and shape of the crystals determine the actual drug application, dissolution and bioavailablity, dose uniformity, processability of the drug product:

The size of the crystals determines how quickly they dissolve in the body. Smaller crystals generally dissolve faster due to their larger surface area relative to their volume, which can improve the drug’s bioavailability—how effectively it is absorbed and used by the body. A uniform size distribution ensures that the dissolution rate is consistent, leading to predictable drug performance and therapeutic outcomes.

In drug manufacturing, consistent crystal size and distribution help ensure that each dosage form (like a tablet or capsule) contains the same amount of active pharmaceutical ingredient (API). If the crystals vary widely in size, it can lead to uneven distribution of the API in the dosage form, resulting in variability in drug potency and potentially impacting patient safety.

Crystals with a narrow size distribution are easier to handle and process. They flow more uniformly through manufacturing equipment, mix evenly with excipients (inactive ingredients), and compress more consistently into tablets. This reduces the risk of production issues like segregation (where particles separate based on size), uneven tablet weights, or poor compaction, leading to more efficient and reliable manufacturing processes.

The size and distribution of crystals can affect the physical and chemical stability of the drug. For example, larger or irregularly shaped crystals might be more prone to breaking down or undergoing unwanted transformations, which could compromise the drug’s stability and shelf life. Consistent size and distribution help maintain the integrity and stability of the drug over time.

Crystallization conditions, including the size and distribution of crystals, can influence which polymorphic form of the API is produced. Different polymorphs can have different solubility, stability, and bioavailability. A controlled crystallization process that produces a uniform size distribution helps in consistently obtaining the desired polymorphic form, which is critical for maintaining drug efficacy and safety.

Challenges for batch produced crystalline API substances towards the change to drug product

While seeded batch crystallized APIs are in the correct polymorphic state and production is sufficiently consistent, the produced drug substance usually needs to be re-engineered towards its desired size and shape for its application. Hence, the addition of one or more additional process steps besides classic seeding, growing, filtration and drying are necessary: changes in shape and size are done with different grinding and milling techniques- wet or dry – followed by seeving steps to obtain the desired size and particle size distribution, avoiding a too large variability in between the smallest and largest crystals present in the drug product powder prior to final formulation.

Although applied consistently for nearly every produced API substance, any additional process step is very costly due to inherent losses of drug product for each different additional step. Also recycling of lost material during these steps comes at a high cost to work up this product to desired properties, if even possible.

Secoya Crystallization Technology’s unique proposition

At Secoya, we have developed a unique crystallization process that allows to reduce the total number of process steps to its bare minimum from drug substance to drug product. We bring the drug substance in solution, and we generate the final CMAs of the drug product in one single process step; followed by filtration and drying. No hustle anymore to generate correctly sized seeds, no more grinding, milling and sieving of the drug products. As a true benefit, our technology bridges completely the drug substance manufacturing with the drug production facility with the direct use of the manufactured API powder.