InstaDrop

Integrated platform for simple and double emulsion

Developed by our microfluidic experts, the InstaDrop instrument was designed to allow a fast and easy set-up for precise, repeatable and cost-effective single or double encapsulation processes.

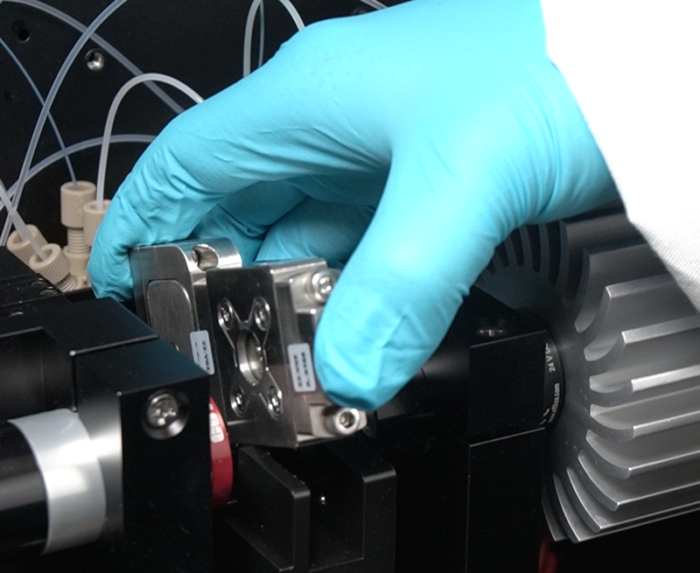

Despite its compact design, the InstaDrop integrates everything required to generate microbeads and micro-capsules with the RayDrop®.

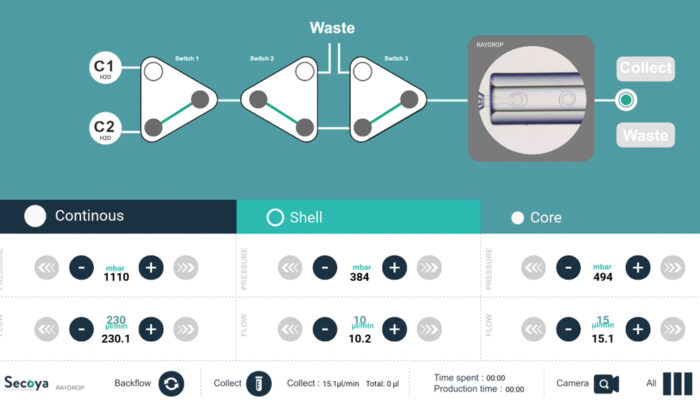

Thanks to its large touchscreen, valves, flowmeters and pressure controllers can be easily controlled to obtain the optimal parameters. Starting up a droplet generation process has never been so easy!

During the process, a suitable optical system guarantees the optimum visualisation of the emulsification inside the RayDrop® generator.

And because it’s powered by the RayDrop® device, the InstaDrop allows a precise formulation of a wide range of microbeads or microcapsules. (PLGA, Chitosan, Alginate,…)

Perfect control of emulsion production

The Secoya emulsification technology is based on the integration of the most efficient microfluidic technologies in a robust stainless-steel equipment.

The way we produce droplets, particles and capsules relies on the use of couples of capillaries perfectly aligned in a metallic reservoir. The first capillary is terminated with a 3D-printed nozzle and injects the droplet phase in the junction. The second one is the only output of the system, so it collects both phases, the droplet phase and the continuous phase filling the reservoir under pressure.

The droplets are produced by the controlled squeezing of the droplet phase by the continuous phase at the entrance of the collection capillary

- Controlled and targeted release

- Dosing flexibility

- Precise loading of cargo (API, cells…)

- Combination product

- Taste Masking

- Fast and easy set-up

- Easy adaptation to user’s formulation

- Handling of low volume samples for screening purposes

- Flow and emulsion production control through large touchscreen

- Compatible with the single and double emulsion RayDrop®

| Description | Product |

| Single and double emulsion production device | Compatible with any RayDrop® device |

| Fluid handling system | • 3 pressure controllers (0-7 Bars) • Solenoid valves • Tubing: 1/16” PFA; 1/32” PEAK • 2 µm PEAK inline Filters |

| Reservoirs | • Continuous phase: 1*50mL Pcap with 50mL Falcon tube • Shell Phase: 2*15mL Pcap with 15mL Falcon tube • Core Phase: 2*15mL Pcap with 15mL Falcon tube |

| Flow meters | • Continuous phase: 0-1 mL/min (water) • Shell Phase: 0-120 µl/min (water) • Core Phase: 0-120 µl/min (water) |

| Optical system | • High power LED • Colour camera with microscopic objective • XYZ translation stages |

| Wetted materials | • PP, FFKM, PFA, PEAK, GLASS, SS316L, PCTFE |

| Unit dimensions | 85 x 51 x 48 cm (L x W x H) |

| Weight | 40 kg |

| Power supply | 230 V (110 V upon request) |

REQUEST A DEMO

| Thank you for Signing Up |