Emulsification

Perfect control of emulsion production

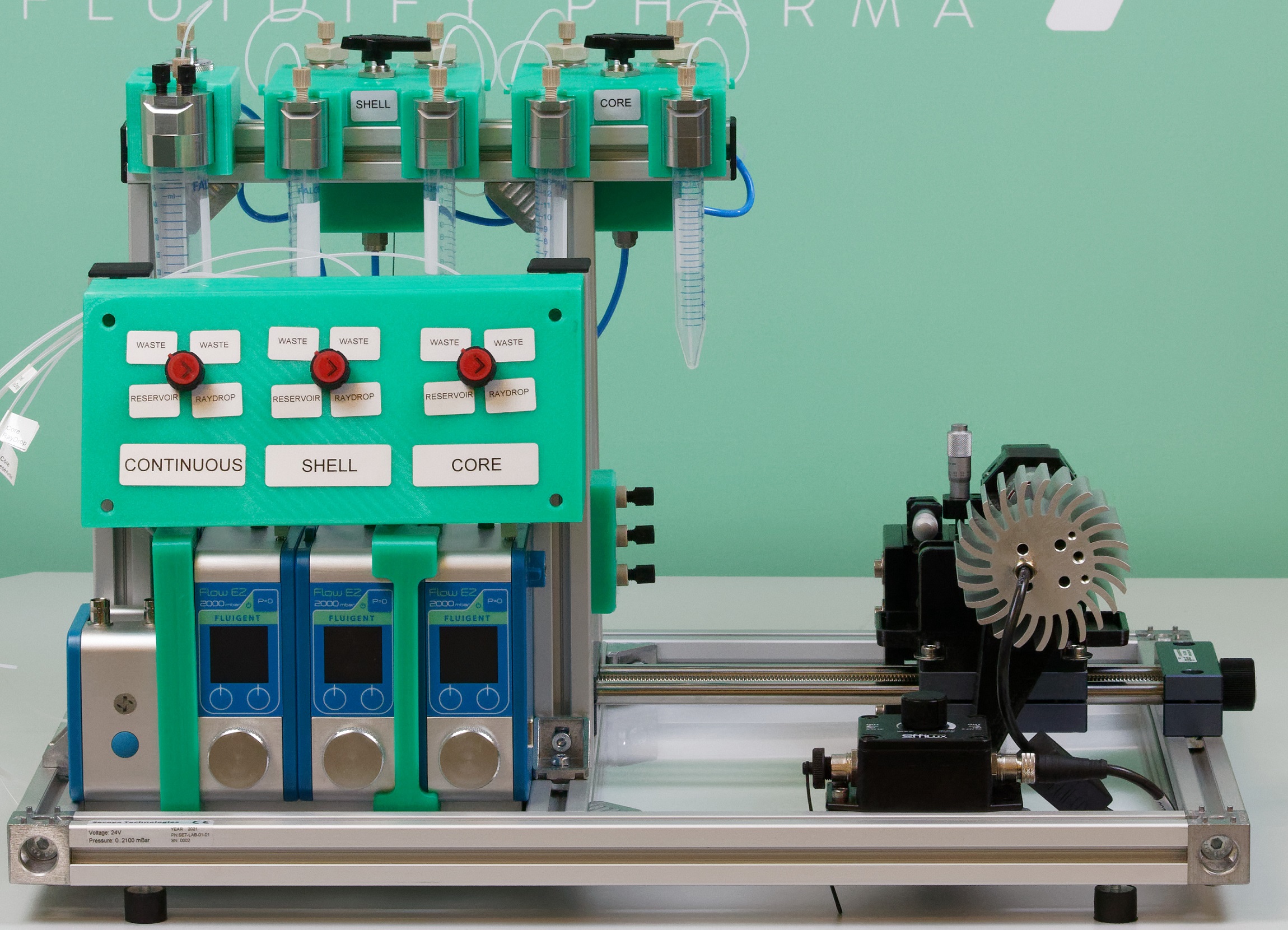

The Secoya emulsification technology is based on the integration of the most efficient microfluidic technologies in a robust stainless-steel equipment.

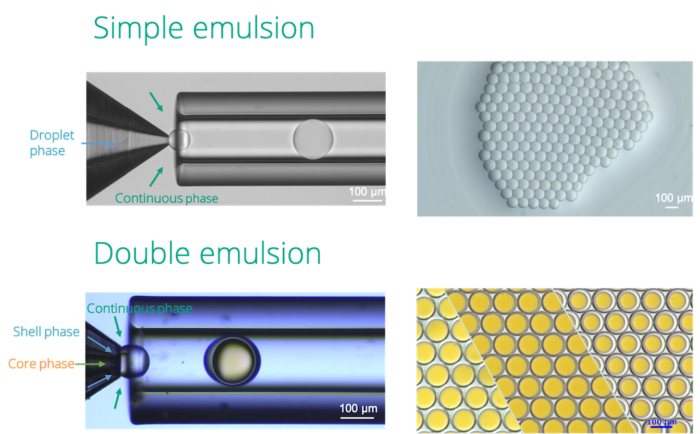

The way we produce droplets, particles and capsules relies on the use of couples of capillaries perfectly aligned in a metallic reservoir. The first capillary is terminated with a 3D-printed nozzle and injects the droplet phase in the junction. The second one is the only output of the system, so it collects both phases, the droplet phase and the continuous phase filling the reservoir under pressure.

The droplets are produced by the controlled squeezing of the droplet phase by the continuous phase at the entrance of the collection capillary

Robust and reliable technology

Our unique integration of a microfluidic technology in a robust device allows us to produce droplets and particles with the key benefits of both worlds: a high control of the particle size and a robust long-run production process.

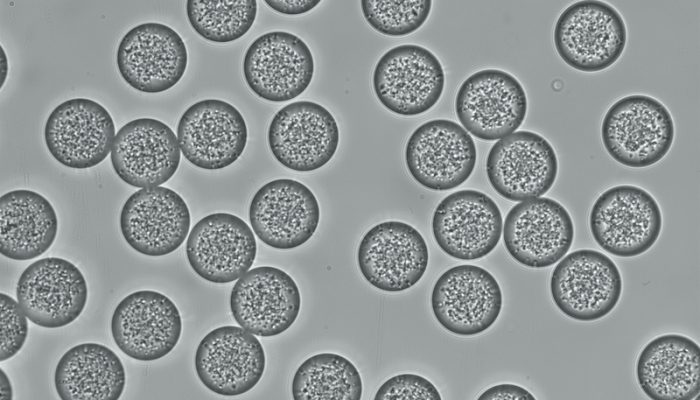

- Particle size : 10 to 200 µm

- API encapsulation efficiency : >95 % (e.g. in PLGA)

- Size distribution : dispersity <2%

- High frequency : > 1000 droplets per second (kHz) per injector

- Surfactant free : no need of surfactant

- Robustness : as no coating is required inside the capillaries, compatibility with long-run production

- Encapsulation versatility : both hydrophobic and hydrophilic ingredients can be encapsulated using the same technology

- Scalability : through number-up

From lab to industrial scale

- Our R&D device, called Raydrop®, and integrative platform are currently available from our reseller Fluigent.

- The scaling up from g/hour to kg/week of finished product is achieved through the numbering-up of the injectors inside a chamber first (base unit), and then through the numbering-up of the base unit.

- Adapted for decentralized production through easy and consistent duplication

Potentiel applications

- Monodispersed PLGA particles

- Monodispersed particles of UV-curable resin

- Efficient encapsulation of active ingredients such as proteins, genetic material and fragrances, whether hydrophobic or hydrophilic

- Encapsulation of active ingredient non soluble in the solvent used to dissolve the polymer

Want to know more about the EMULSIFICATION TECHNOLOGY?

Want to know more about the EMULSIFICATION TECHNOLOGY?

| Thank you for Signing Up |